Introduction

Ethyl acetate is a vital chemical compound widely used across multiple industries such as pharmaceuticals, food and beverages, paints, coatings, and adhesives. It is an organic ester derived from ethanol and acetic acid, characterized by a fruity smell and volatility. Due to its solvent properties and relatively low toxicity, ethyl acetate is a preferred choice in many applications. Establishing an Ethyl Acetate Manufacturing Plant offers a lucrative business opportunity given the increasing global demand for solvents across various industries. This Ethyl Acetate Manufacturing Plant Project Report provides an in-depth look into the different aspects of setting up an ethyl acetate manufacturing plant, including the production process, market potential, financial considerations, and frequently asked questions (FAQs).

Understanding Ethyl Acetate

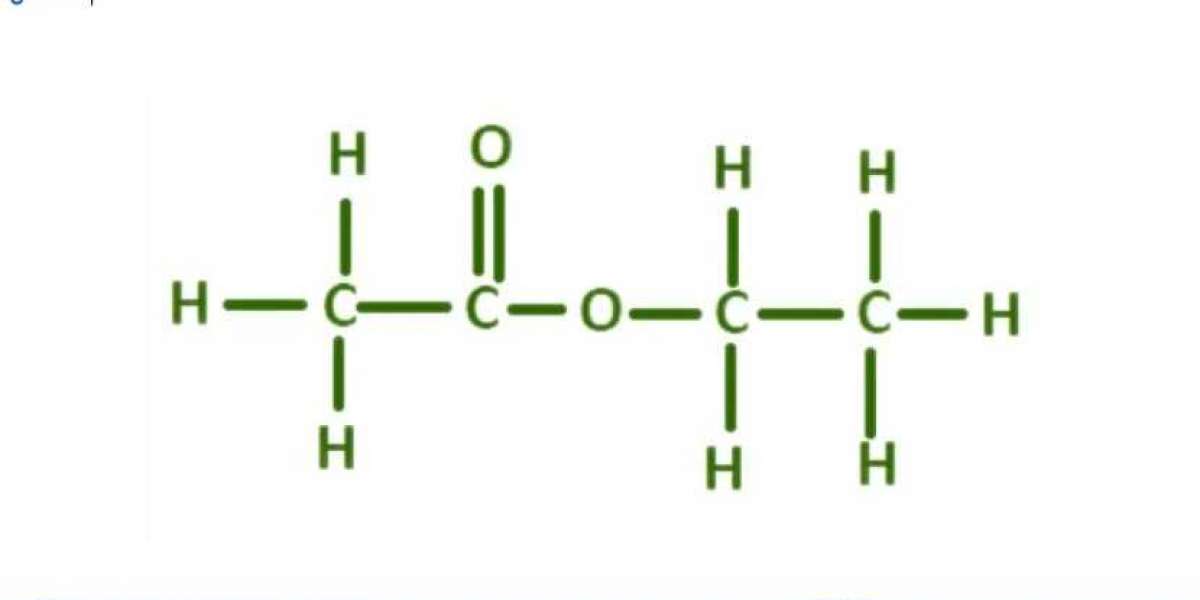

Ethyl acetate (C4H8O2) is a clear, colorless liquid with a fruity odor. It is primarily used as a solvent due to its ability to dissolve a wide range of substances. Ethyl acetate is employed in several industries, including:

- Pharmaceuticals: It is used in the production of drugs and as an extraction solvent for various compounds.

- Adhesives: Ethyl acetate plays a key role in the formulation of glues and adhesives.

- Paints and Coatings: Due to its volatility and low toxicity, ethyl acetate is commonly used in paints, varnishes, and coatings.

- Food and Beverage: It is used as a flavoring agent in food products and alcoholic beverages.

Market Demand for Ethyl Acetate

The global demand for ethyl acetate is expected to grow steadily due to its extensive use in numerous industries. Several key factors are driving this growth:

Expansion in the Coatings Industry: As construction activities increase globally, the demand for paints, coatings, and varnishes—key applications for ethyl acetate—has surged.

Pharmaceutical Growth: The pharmaceutical sector continues to expand, especially post-pandemic, increasing the need for ethyl acetate as a solvent in drug formulation and production.

Consumer Goods: Ethyl acetate’s use in personal care products like nail polish and perfumes is growing with the rising disposable income and demand for cosmetics.

Sustainability Concerns: Ethyl acetate is seen as a more environmentally friendly solvent due to its biodegradability and relatively low environmental impact compared to other petroleum-based solvents.

Food Industry Demand: The use of ethyl acetate as a food flavoring agent is growing, particularly in processed foods and beverages.

Benefits of Setting Up an Ethyl Acetate Manufacturing Plant

Establishing an ethyl acetate manufacturing plant offers several advantages, including:

Growing Market Potential: The diverse applications of ethyl acetate across multiple industries ensure stable market demand and growth potential.

Eco-Friendly Product: Ethyl acetate is often regarded as a “green” solvent, giving manufacturers a competitive edge in industries looking to reduce environmental footprints.

Wide Range of Applications: Ethyl acetate serves as a key raw material for several industries, allowing manufacturers to cater to a broad customer base.

High Profit Margins: The production of ethyl acetate offers substantial profit margins due to relatively stable raw material costs and increasing product demand.

Export Opportunities: With the growing global demand for solvents, establishing a production plant can open up avenues for export, particularly to developing markets.

Get a Free Sample Report with Table of Contents @

Raw Materials Required for Ethyl Acetate Production

Ethyl acetate is synthesized through the esterification of ethanol and acetic acid. Key raw materials include:

Ethanol: Derived from sugarcane or corn fermentation, ethanol serves as one of the main components in the production process.

Acetic Acid: A primary ingredient, often produced via the carbonylation of methanol.

Catalysts: Acid catalysts such as sulfuric acid or hydrochloric acid are used to accelerate the esterification reaction.

Water: Water is essential for cooling and maintaining temperatures during the reaction process.

Manufacturing Process of Ethyl Acetate

The process for manufacturing ethyl acetate involves several steps, primarily centered around the esterification reaction between ethanol and acetic acid. Here’s a brief breakdown of the process:

Esterification Reaction: Ethanol and acetic acid are mixed in the presence of an acid catalyst to initiate the esterification reaction, forming ethyl acetate and water as by-products.

Ethanol (C2H5OH) + Acetic Acid (CH3COOH)→Ethyl Acetate (C4H8O2)+Water (H2O)\text{Ethanol (C}_2\text{H}_5\text{OH) + Acetic Acid (CH}_3\text{COOH)} ightarrow \text{Ethyl Acetate (C}_4\text{H}_8\text{O}_2) + \text{Water (H}_2\text{O)}Ethanol (C2H5OH) + Acetic Acid (CH3COOH)→Ethyl Acetate (C4H8O2)+Water (H2O)Separation: After the reaction is complete, the resulting mixture is distilled to separate ethyl acetate from water and other reactants.

Purification: The crude ethyl acetate may undergo additional distillation to remove any impurities or remaining reactants, ensuring a high-quality final product.

Cooling and Storage: Once purified, the ethyl acetate is cooled and stored in sealed containers to prevent evaporation and degradation.

Machinery Required for Ethyl Acetate Production

Setting up an ethyl acetate manufacturing plant requires specialized machinery, which includes:

Reactor Vessel: Used for the esterification reaction between ethanol and acetic acid.

Distillation Columns: For separating ethyl acetate from the reaction mixture and purifying the final product.

Heat Exchangers: For maintaining optimal temperature during the reaction and distillation processes.

Storage Tanks: For safely storing raw materials and finished products.

Pumps and Piping Systems: For transferring liquids between different stages of the production process.

Cooling Systems: To control temperature and ensure safe operation.

Financial Considerations: Investment and Profitability

Setting up an Ethyl Acetate Manufacturing Plant requires a significant initial investment, but the profitability prospects are promising. Key financial components include:

Initial Investment: This involves capital for purchasing machinery, construction of the manufacturing facility, and procurement of raw materials. The initial capital expenditure could range between $1 million and $10 million, depending on plant size and production capacity.

Operating Costs: Recurring expenses such as labor, raw materials (ethanol and acetic acid), energy consumption, and maintenance will factor into operational costs.

Profit Margins: Ethyl acetate production typically offers profit margins ranging from 15% to 30%, depending on the scale of operations and market conditions.

Return on Investment (ROI): With rising demand for ethyl acetate across industries, the return on investment is expected to be favorable, especially when operating at high efficiency.

Market Potential and Target Industries

Ethyl acetate’s versatile applications make it a sought-after product in numerous industries, including:

Paints and Coatings: Widely used as a solvent in paints, varnishes, and coatings for its rapid evaporation rate and compatibility with resins.

Pharmaceuticals: Used as a solvent in the production of active pharmaceutical ingredients (APIs) and in drug formulation.

Adhesives and Sealants: A key component in the formulation of various adhesives, particularly in packaging and construction.

Cosmetics and Personal Care: Utilized in products like nail polish, perfumes, and cosmetics due to its low toxicity and pleasant odor.

Food and Beverage: Ethyl acetate is used as a flavoring agent and solvent in food and beverage production, particularly in flavor extracts.

Regulatory Considerations

Compliance with health, safety, and environmental regulations is critical for operating an ethyl acetate manufacturing plant. Key regulatory aspects include:

Environmental Regulations: Compliance with regulations governing air emissions, waste disposal, and water treatment (EPA standards in the U.S. or corresponding agencies elsewhere).

Safety Standards: Occupational safety regulations must be followed to ensure worker safety, particularly when handling hazardous materials.

ISO Certifications: Obtaining certifications like ISO 9001 (quality management) and ISO 14001 (environmental management) can improve the plant's credibility and marketability.

Frequently Asked Questions (FAQs)

What is ethyl acetate?

Ethyl acetate is a colorless, volatile liquid used as a solvent in a wide range of industries, including pharmaceuticals, paints, adhesives, and food processing.What are the raw materials required to produce ethyl acetate?

The primary raw materials are ethanol and acetic acid, which react in the presence of an acid catalyst to produce ethyl acetate.What industries use ethyl acetate?

Industries that use ethyl acetate include pharmaceuticals, paints and coatings, adhesives, cosmetics, and food and beverage manufacturing.How much investment is required to set up an ethyl acetate manufacturing plant?

The initial investment typically ranges from $1 million to $10 million, depending on the scale and technology used.What is the expected profitability in ethyl acetate manufacturing?

Profit margins typically range from 15% to 30%, depending on production efficiency and market conditions.

Related Reports

https://www.expertmarketresearch.com/reports/lubricating-oil-additives-market

https://www.expertmarketresearch.com/reports/gelatin-market

https://www.expertmarketresearch.com/articles/top-4-companies-in-the-global-industrial-mixers-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au