What is Drop Testing?

Drop Tester g is a method used to assess the durability of a product's packaging by simulating the impacts and forces it might experience when dropped during shipping and handling. The test involves dropping a package from a specified height and observing the effects on both the packaging and the product inside. This helps determine if the packaging provides adequate protection or if improvements are needed.

The primary purpose of drop testing is to ensure that the packaging can protect the product from damage, even when subjected to harsh conditions. This is particularly important for fragile items, such as electronics, glassware, or perishable goods, which require special care during transportation.

Why is Drop Testing Crucial?

Drop testing is crucial for several reasons:

- Product Protection: The most obvious benefit of drop testing is that it helps protect the product inside the packaging. By simulating real-world conditions, manufacturers can identify potential weaknesses in their packaging and make necessary adjustments before the product reaches the consumer.

- Compliance with Standards: Many industries have specific standards that packaging must meet to ensure product safety. Drop Testing helps manufacturers comply with these standards, reducing the risk of product recalls and ensuring customer satisfaction.

- Cost Efficiency: Packaging that fails during transit can result in damaged products, leading to returns, replacements, and increased costs. By conducting thorough drop testing, manufacturers can reduce these risks and ensure that their packaging is cost-effective.

- Brand Reputation: In today’s market, brand reputation is everything. A damaged product can lead to negative reviews and a loss of customer trust. Drop testing helps maintain a positive brand image by ensuring that products arrive in perfect condition.

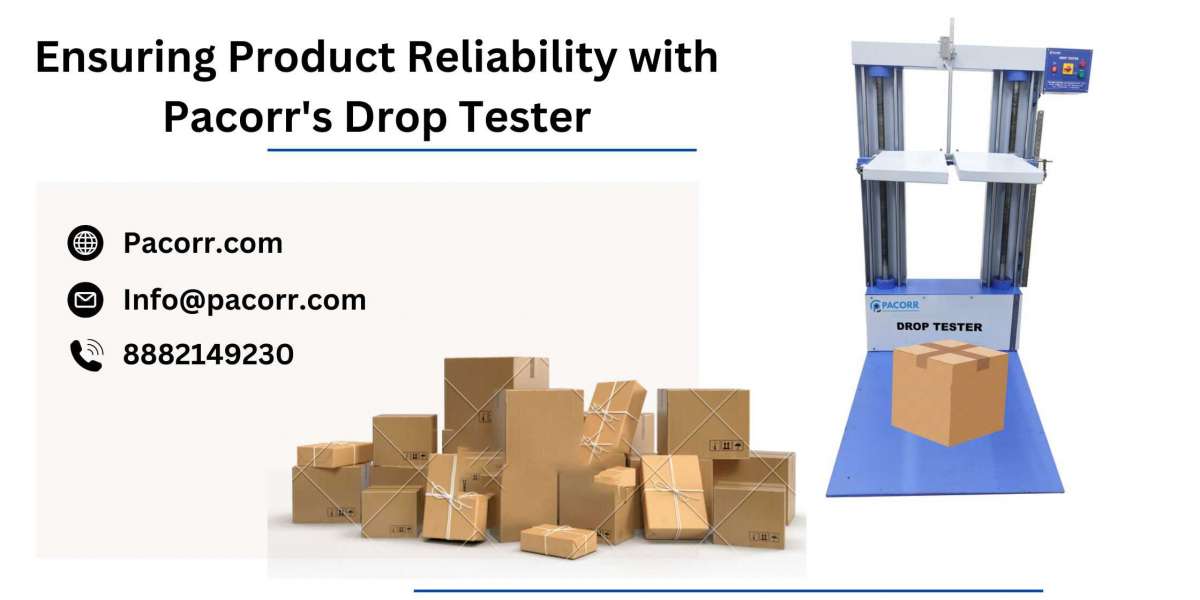

Features of Pacorr’s Drop Tester

Pacorr’s Drop Tester Price is an advanced instrument designed to perform drop tests on various types of packaging. Here are some key features that make our Drop Tester stand out:

- Precision Engineering: The Drop Tester is engineered with precision to ensure accurate and repeatable results. It allows manufacturers to set the exact drop height, ensuring that the test conditions are consistent.

- Versatile Applications: Our Drop Tester is versatile and can be used for testing a wide range of products, from small electronic devices to large industrial components. The adjustable platform and customizable settings make it easy to adapt the test to different packaging sizes and weights.

- User-Friendly Interface: The tester is equipped with a user-friendly interface that allows operators to easily control the test parameters and monitor the results. This ensures that the testing process is both efficient and straightforward.

- Durability: Built with high-quality materials, the Drop Tester is designed to withstand continuous use in industrial settings. Its robust construction ensures long-term reliability, making it a valuable investment for any manufacturer.

- Safety Features: Safety is a top priority at Pacorr, and our Drop Impact Tester includes several safety features to protect both the operator and the product being tested. These include emergency stop buttons, protective guards, and non-slip platforms.

Applications of Drop Testing

Drop testing is widely used across various industries to ensure the durability and safety of packaging. Some common applications include:

- Consumer Electronics: Electronics are particularly vulnerable to damage during transit, making drop testing essential for packaging design. Drop tests help ensure that devices such as smartphones, laptops, and tablets arrive intact.

- Food and Beverage: Drop testing is used to evaluate the packaging of food and beverages to prevent spillage and contamination during transportation.

- Pharmaceuticals: In the pharmaceutical industry, drop testing is crucial to ensure that medicines and medical devices are securely packaged and protected from damage.

- Automotive Parts: Drop testing is used to evaluate the packaging of automotive parts to prevent damage during shipping and ensure that components arrive safely at their destination.

Conclusion

In a world where consumers expect perfection, ensuring that your packaging can withstand the rigors of transit is more important than ever. Pacorr’s Drop Tester provides manufacturers with the tools they need to conduct accurate and reliable drop tests, ensuring that their products arrive in perfect condition every time.

Whether you’re in the electronics, food, pharmaceutical, or automotive industry, drop testing is an essential step in maintaining product quality and customer satisfaction. With Pacorr’s Drop Testing, you can be confident that your packaging meets the highest standards of durability and reliability. Invest in quality, protect your brand, and deliver excellence with Pacorr Testing Instruments.

For more information about Pacorr’s Drop Tester and how it can benefit your business, please visit our website at Pacorr Testing Instruments.